| View previous topic :: View next topic |

| Author |

Message |

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Wed Nov 04, 2009 7:59 pm Post subject: Custom 105/2-based project Posted: Wed Nov 04, 2009 7:59 pm Post subject: Custom 105/2-based project |

|

|

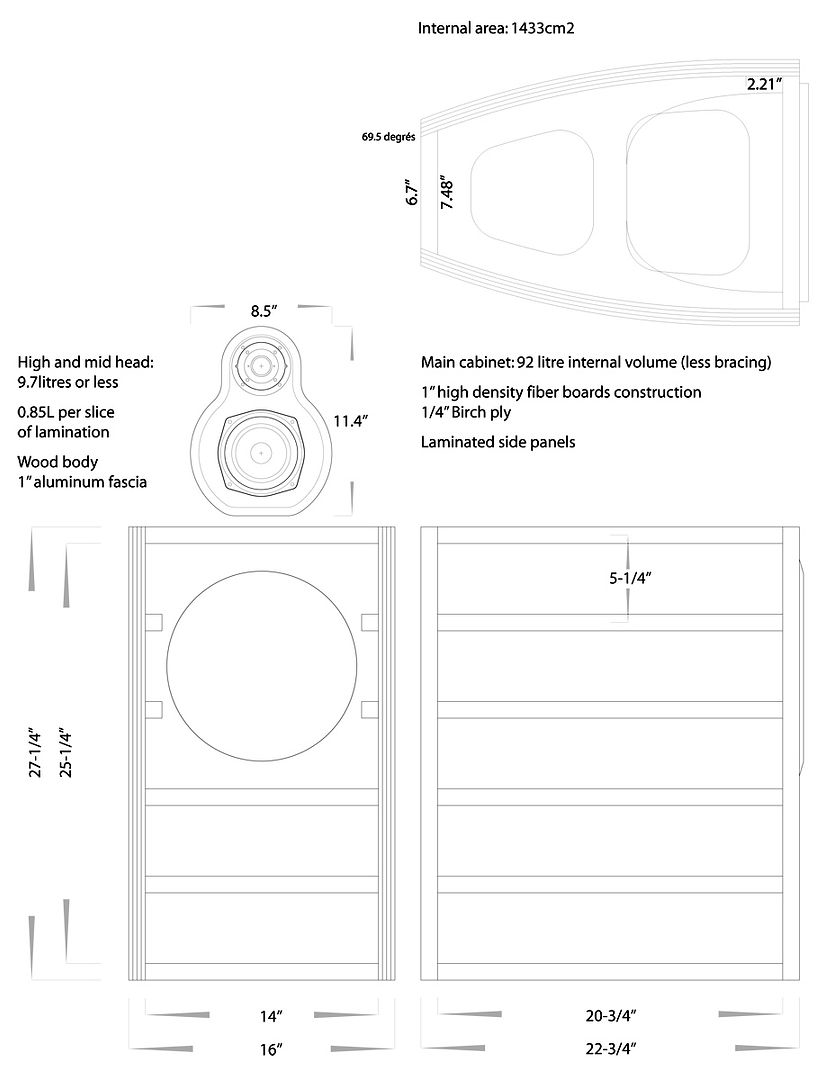

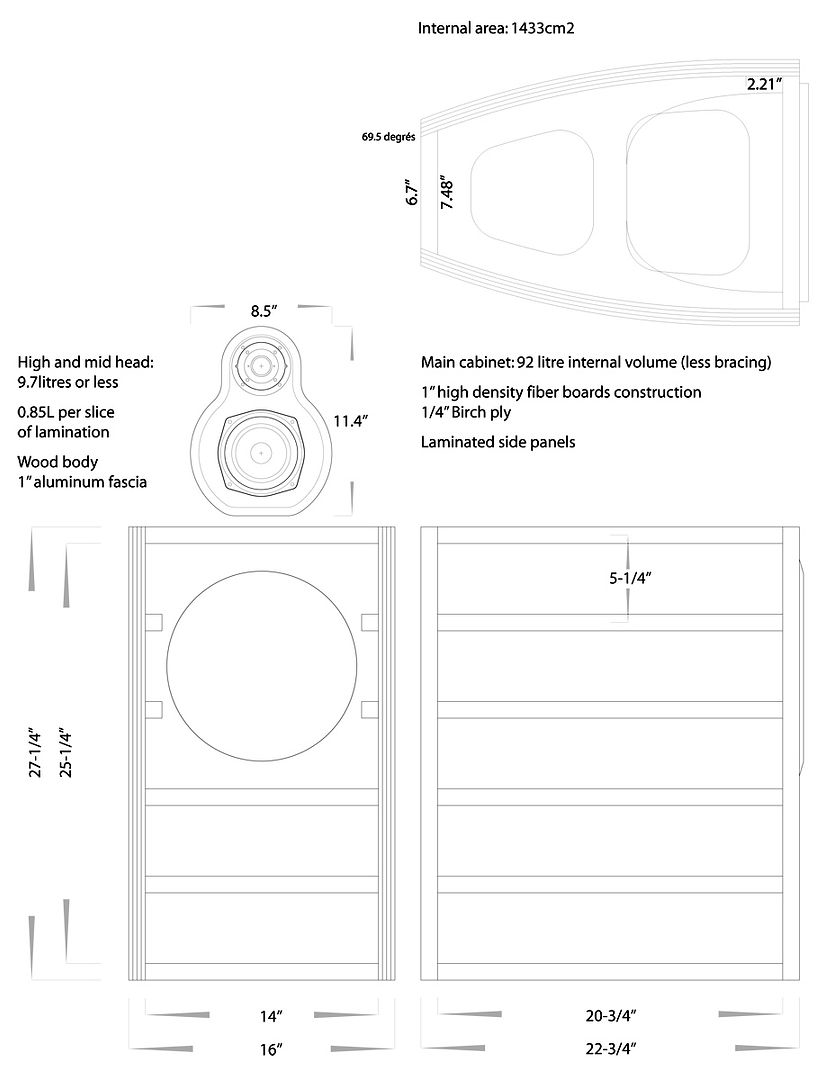

The construction of a set of 105/2-based speakers has started last week. I wanted to you use 1" HDF and not MDF, but as I was able to get 1" thick high density boards 20 years ago, it seems it is more difficult nowadays. Therefore I picked 1" MDF. The cabinets are braced horizontally every 5-1/4" anyway, so I have no fear in regard of stiffness and vibrations. The only reinforcement not pictured is a vertical bracing, in between every cross section to tie the bottom and top panels. The sides are curved, braced and won't vibrate as curved surfaces are more resistant to vibrations.

The sides will be built with four layers of 1/4" MDF, glued one after the other, with a few days in between each operation to allow glue to 100% dry.

I am not set yet on which finish to use. Maple, rosewood veneer. I don't know. But final tonality will be redish...

1-1/2" high density foam will used inside the cabinets and crossovers will be located in a separate box. The crossovers will be (at the beginning) stock-specced 105/2 units with fresh caps.

Heads are slices of hard maple wood, glued together to form a volume. Slices are cut by CNC.

The bass module will be just as high as a Calinda, barely narrower than a 105/2 but close to 2 feet deep. Volume is about 45% more than stock 105/2. So, bigger enclosure (within Kef's own guidelines for a sealed enclosure) and stiffer cabinet. Aiming at improving the quality of the lower bass.

I will probably start assembling the frames this weekend (front and rear panels with top, bottom and intermediate sections). Then bending the sides in 4 different steps. Will post some pictures showing the different production steps.

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds |

|

| Back to top |

|

|

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Sun Nov 29, 2009 7:43 pm Post subject: Posted: Sun Nov 29, 2009 7:43 pm Post subject: |

|

|

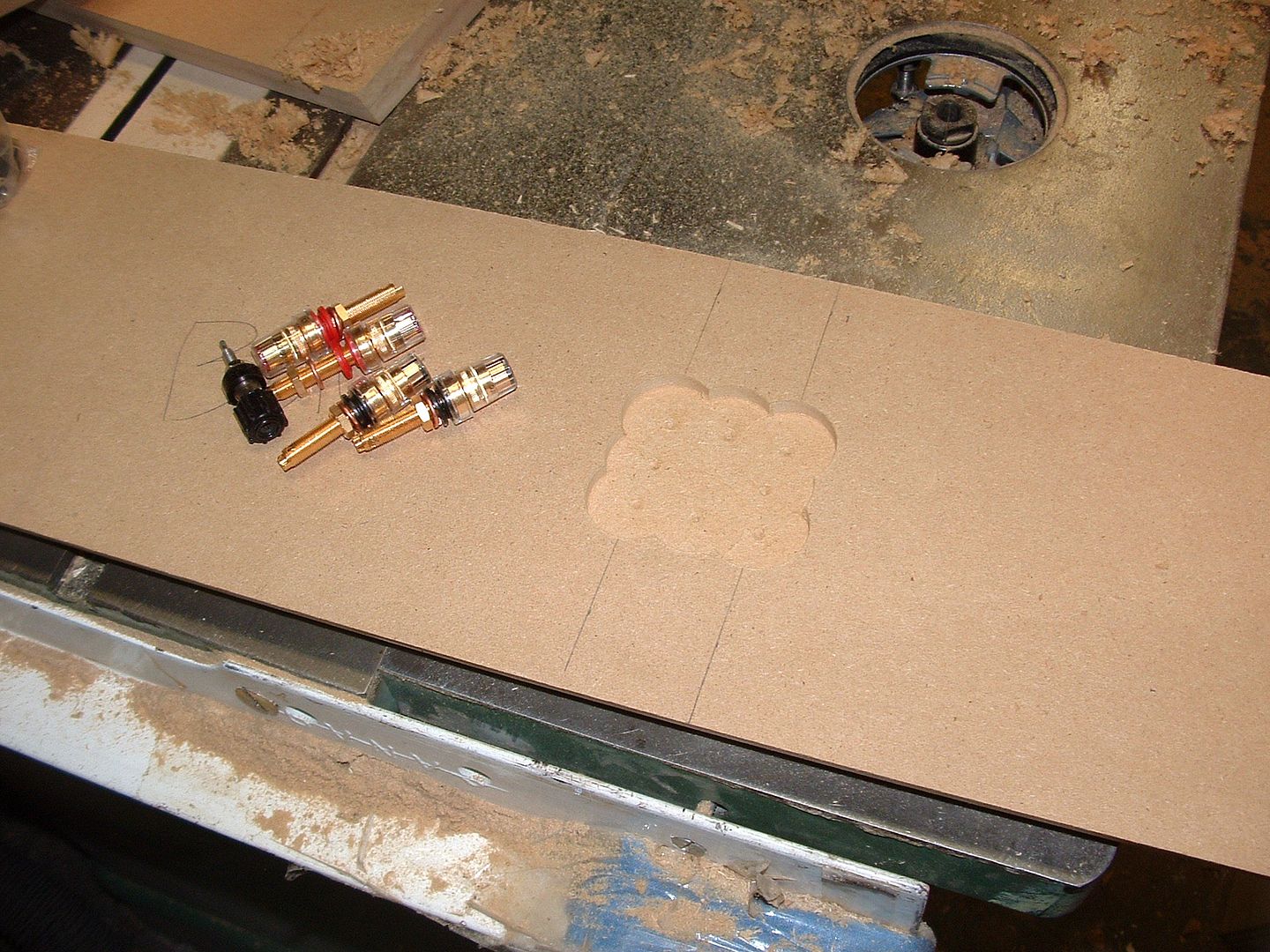

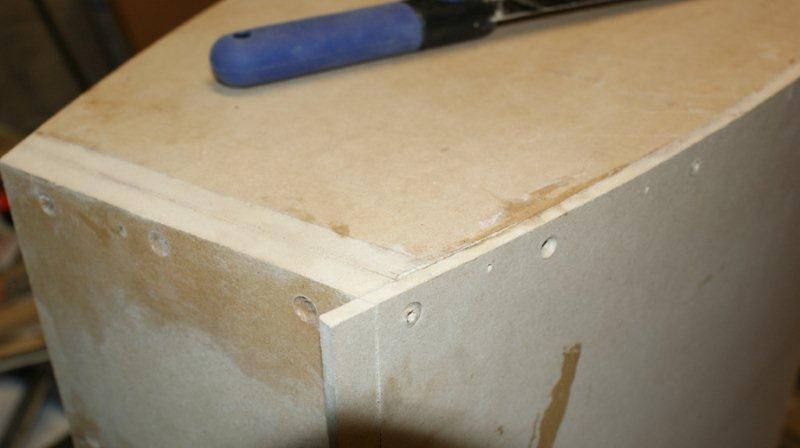

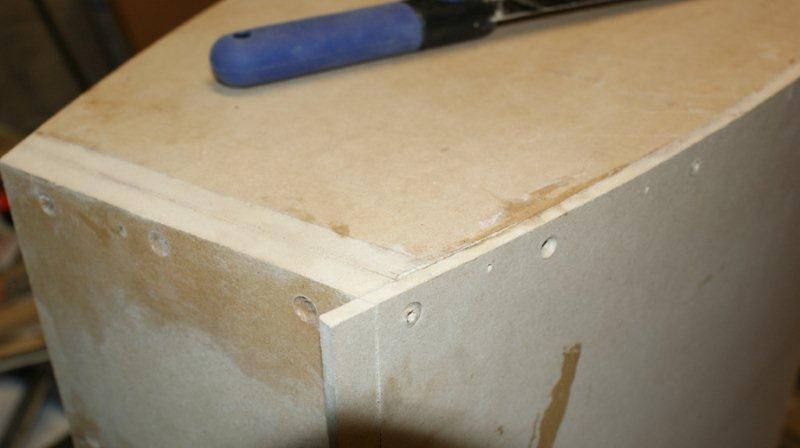

So, here are a few pictures of the first step in making my custom 105/2s. In fact, they are the second step as the first one involved having the 1" MDF cut by CNC for accuracy and repeatitivity. After a first mock-up to ensure everything fitted together, we teared the assembly apart for the final gluing (uisng urethane glue) and screwing.

We will allow 24 hours for the glue to cure, then we will lay the 4 layers of 1/4" MDF on the sides, following the smooth curve.

Inventory of the components. My friend is holding the parts for me.

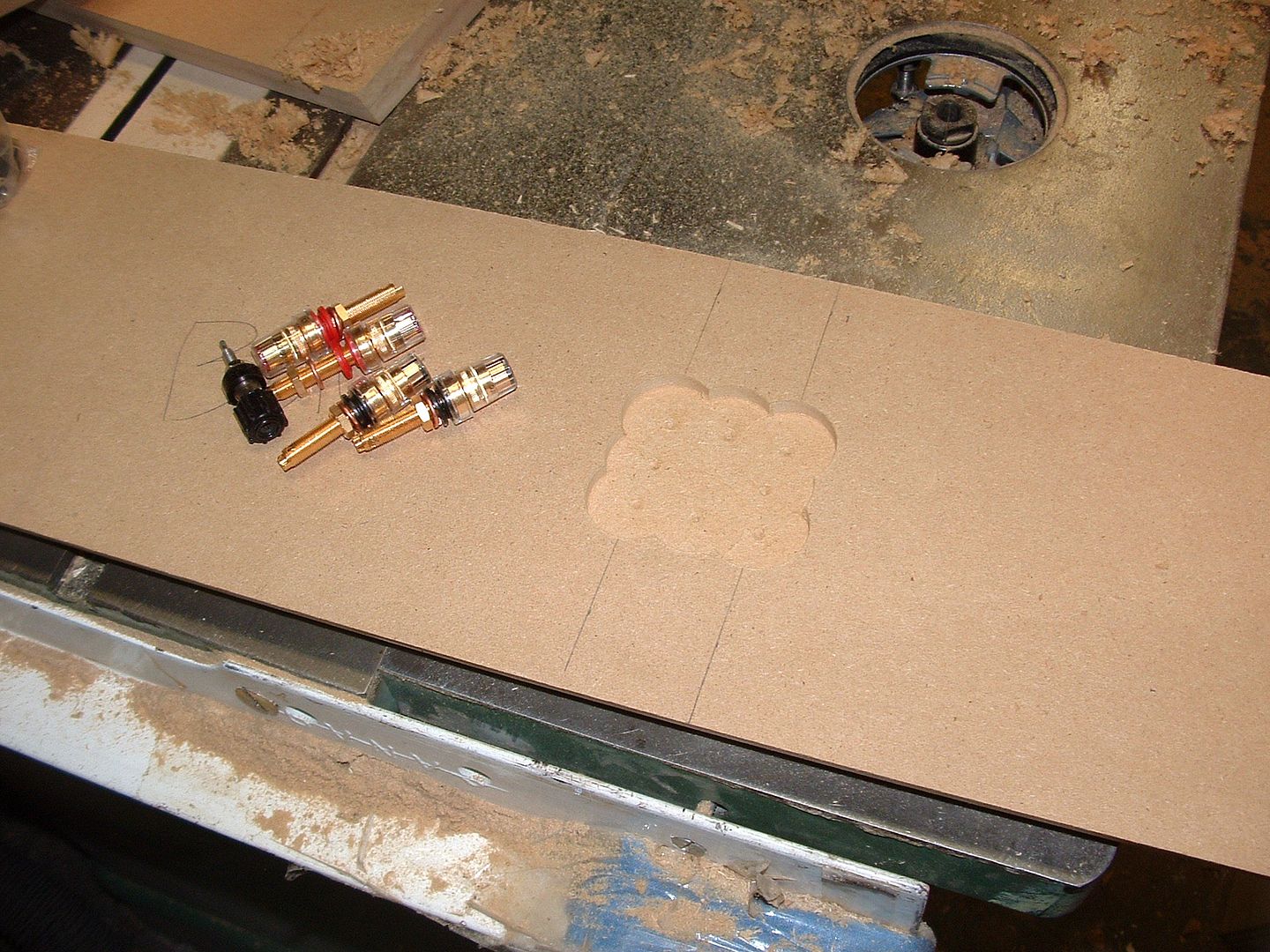

Making the recessed holes for the connectors

Mocking-up the first enclosure

Enclosures are glued. Jigs removed. Left to cure for 24 hours.

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds |

|

| Back to top |

|

|

TL 200

Senior Contributor 100+

Joined: 27 Jul 2009

Posts: 141

Location: Emmer-Compascuum The Netherlands

|

Posted: Mon Nov 30, 2009 6:21 pm Post subject: Posted: Mon Nov 30, 2009 6:21 pm Post subject: |

|

|

Beautifull,

looks like good craftmanship to me.

Wish you a lot off succes,

greets from Holland, Bert |

|

| Back to top |

|

|

proffski

Über Contributor 1000+

Joined: 22 Aug 2003

Posts: 1297

Location: Tewkesbury UK

|

Posted: Mon Nov 30, 2009 8:45 pm Post subject: Posted: Mon Nov 30, 2009 8:45 pm Post subject: |

|

|

Absolutely amazing craftsmanship, keep the pictures coming! Stunning project!!!

_________________

I contend that for a nation to try to tax itself into prosperity is like a

man standing in a bucket and trying to lift himself up by the handle.

-Winston Churchill |

|

| Back to top |

|

|

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Thu Dec 10, 2009 7:09 pm Post subject: Posted: Thu Dec 10, 2009 7:09 pm Post subject: |

|

|

Here's a small follow-up.

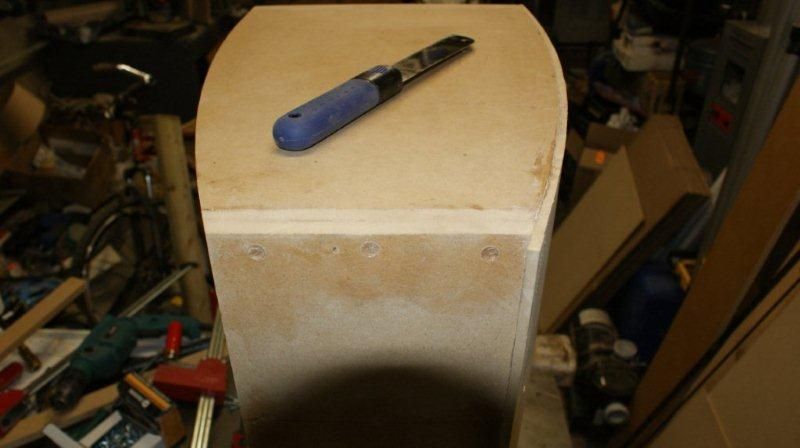

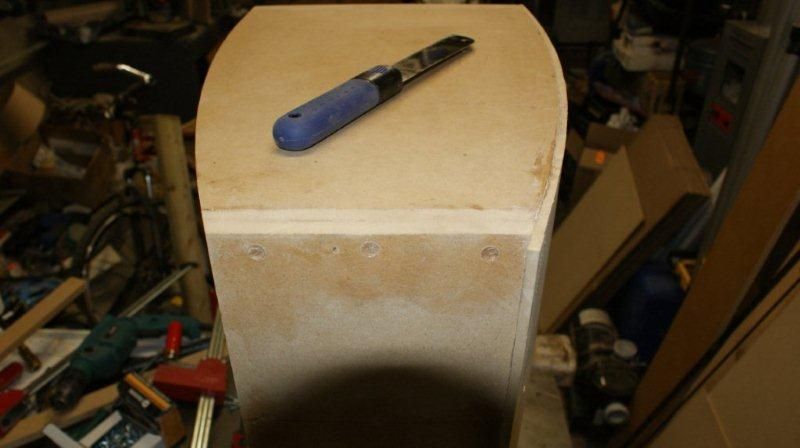

One layer was glued. We tested the process and it works. This is a 1/4" sheet. Four layers will be applied for a total thickness of 1"

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds |

|

| Back to top |

|

|

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Mon Jan 11, 2010 4:58 am Post subject: Follow-up Posted: Mon Jan 11, 2010 4:58 am Post subject: Follow-up |

|

|

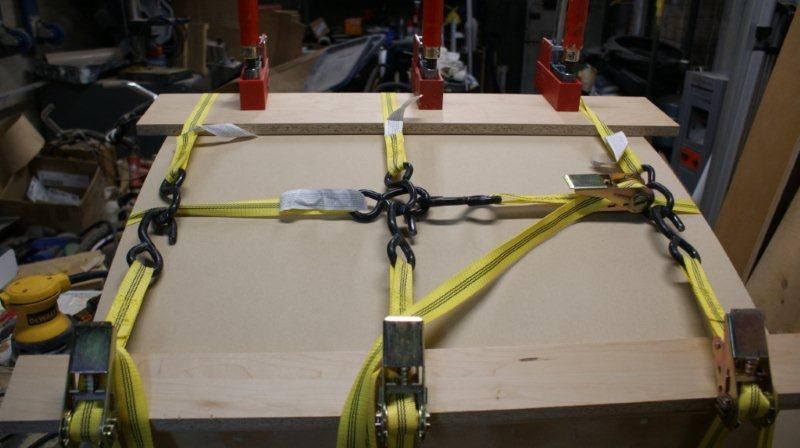

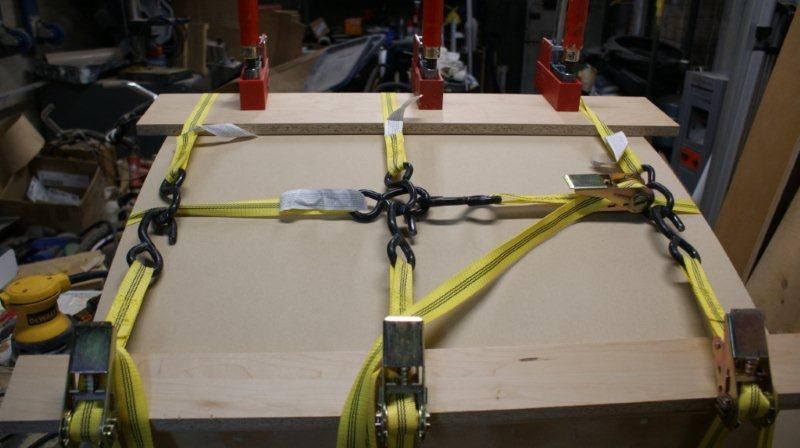

It's been a long time since I posted a follow-up. Cabinets are done with the second stage: the 4 layers of 1/4" MDF. The first layer was glued with epoxy and screwed to the skeleton. All three remaining layers were glued one by one with standard carpenter glue and using straps to bend the MDF sheets and keep the bonded until the glue dried. About 24 hours per layer. Next step will be to apply maple veneer and dye it an orangey red.

A great thank to my buddy Steve who has been carrying all the work after we did the structure together. Every step of layering the 1/4" sheets requires 30-45 minutes, with 24 hours in between. So, it wasn't practical for me to drive across town for a 45 minute task. 16 times. So, hat off to Steve for his dedication. One thing I forgot to mention is that each cabinet weights in the vicinity of 90lbs (41Kg). Empty.

There were basically two reasons that lead me to use a parabolic shape for the opposing sides of that cabinet. The primary goal was to avoid standing waves. The second goal was to make the big cabinet look smaller. They are 27" high by 16" wide and about 22" deep. And they won't look too imposing in my living room. Small Kef 105-2 enclosures will be put on top for the mid and high drivers.

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds |

|

| Back to top |

|

|

Parts

Senior Contributor 100+

Joined: 13 Jan 2006

Posts: 181

Location: Edinburgh

|

Posted: Tue Jan 12, 2010 11:57 pm Post subject: Posted: Tue Jan 12, 2010 11:57 pm Post subject: |

|

|

Superb llooking!

Will you be routing and rounding the edges of the cabinet in any way? |

|

| Back to top |

|

|

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Wed Jan 13, 2010 4:40 am Post subject: Posted: Wed Jan 13, 2010 4:40 am Post subject: |

|

|

If I had laquered the current MDF, then I would have rounded all the edges. But as I will stick some maple veneer, I need to keep the sharp edges.

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds |

|

| Back to top |

|

|

speakerguru

Über Contributor 1000+

Joined: 18 Nov 2005

Posts: 1192

Location: Green Hut, Tovil

|

Posted: Wed Jan 13, 2010 2:11 pm Post subject: Posted: Wed Jan 13, 2010 2:11 pm Post subject: |

|

|

| Maple veneer....mmmm....nice. Plain? Quilted? Birds-eye? Fiddleback?..... |

|

| Back to top |

|

|

proffski

Über Contributor 1000+

Joined: 22 Aug 2003

Posts: 1297

Location: Tewkesbury UK

|

Posted: Wed Jan 13, 2010 2:38 pm Post subject: Posted: Wed Jan 13, 2010 2:38 pm Post subject: |

|

|

There are sveral of us here in Gloucestershire keep checking regularly for more pictures and progress reports...

Lee sure knows as to how keep the suspense going, should be in films directing!

_________________

I contend that for a nation to try to tax itself into prosperity is like a

man standing in a bucket and trying to lift himself up by the handle.

-Winston Churchill |

|

| Back to top |

|

|

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Wed Jan 13, 2010 3:01 pm Post subject: Posted: Wed Jan 13, 2010 3:01 pm Post subject: |

|

|

At this stage, it's my friend Steve doing all the work, layer per layer. One layer or two per week. He's is a hobbyist and works in his basement while his two young daughters take a lot of his time. Bringing the girls to ballet school, then painting school on Saturdays, etc. Doing homework on week days. Etc. Therefore, he works on the enclosures only on free time. And just like good whiskey, great things take time. No need to rush.

In the meanwhile, I am fixing and upgrading my "new" Quad 606. For now, one channel blows fuel on switch-on... I might just as well bring it to a local Quad/Marantz independent specialst to find the glitch, then buy Dada's 606 upgrade kit.

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds

Last edited by Lee in Montreal on Thu Jan 14, 2010 1:42 pm; edited 2 times in total |

|

| Back to top |

|

|

SaSi

Senior Contributor 200+

Joined: 24 Aug 2008

Posts: 256

|

Posted: Thu Jan 14, 2010 11:53 am Post subject: Posted: Thu Jan 14, 2010 11:53 am Post subject: |

|

|

Nice work and nice progress there Lee.

I am going along similar lines here. I am building a bass cabinet to use with R107 sats. I have opted for a rather large enclosure (90x40x60 as HxWxD) in centimeters. They are approximately the same dimensions as yours in WxD but almost 1ft taller. And they are rectangular - I understand what you mean with "imposing size".

I am going to use two B300 per cabinet in isobaric configuration to "reduce" the volume requirement down to 160lt for a 18Hz Fc. At least that's the design goal.

I am going to experiment with the first enclosure and various options, including dual woofers in sealed box, single woofer with vent, dual woofers with vent, single woofer with PR (B139) single woofer with dual PRs, and dual woofer with single and dual PRs.

The WinISD simulations seem promising but the PR version seems to suffer from irregular frequency response near the fc and a group delay that increases at a higher frequency than the vented version.

If it all fails, I will at least have a nice large test cabinet with braces an partitions that I will be able to use for tests. |

|

| Back to top |

|

|

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Mon Jan 18, 2010 1:19 am Post subject: Posted: Mon Jan 18, 2010 1:19 am Post subject: |

|

|

More development. One cabinet has been veneered. Next step will be to dye the wood to an orangey red, then several layers of satin finish clear.

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds |

|

| Back to top |

|

|

proffski

Über Contributor 1000+

Joined: 22 Aug 2003

Posts: 1297

Location: Tewkesbury UK

|

Posted: Mon Jan 18, 2010 1:30 am Post subject: Posted: Mon Jan 18, 2010 1:30 am Post subject: |

|

|

Utterly awesome, I sincerely pray that the sound will be as good as the cabinet!

You have made my previous attempts since 1968 look like rubbish, but I will not hold it agains you as long as we get more pictures and the audio reports. STUNNING!

_________________

I contend that for a nation to try to tax itself into prosperity is like a

man standing in a bucket and trying to lift himself up by the handle.

-Winston Churchill |

|

| Back to top |

|

|

Lee in Montreal

Senior Contributor 200+

Joined: 22 Aug 2009

Posts: 231

|

Posted: Mon Jan 18, 2010 3:17 pm Post subject: Posted: Mon Jan 18, 2010 3:17 pm Post subject: |

|

|

Hey Proffski

Thanks for the good word. The goals with that cabinet are extra volume (to the B300's original 90 litre specs), extra cabinet stiffness (thick 1" MDF, curved walls and tons of bracing) and reduction in standing waves (curved walls - which was a problem already addressed in the original 105/2 design with the front and rear panels not being parallel). How will that translate soundwise? I have yet to compare. The improvement will most likely be more "physical" than actually aural. It should lower the system resonance by about 5 hz, as well as the roll-off frequency.

I spent the weekend listening to my 105/2 and Cantata. They are not from the sam planet. I like the mids and highs from the Cantata, while the 105/2 has much better low end. So, it givs me references on which to work.

I was actually considering runnig the mids and highs as dipoles. No enclosures. Just free standing drivers. I am not woried witthe tweeters. But the mids go down to 400Hz. I wonder how it wil behave. I am trying to get to the most natural presentation of sound.

_________________

Current line up

2 sets basic Kef 104/2

2 sets bi-wire Kef 104/2

Plenty of KEF components for a few fun builds |

|

| Back to top |

|

|

|